Shop

-

Turning

add remove

- Milling add remove

-

Drill

add remove

- HSS-Drills add remove

- Compatible Tools add remove

- Sets

- Accessoires add remove

- SPECIAL OFFERS

- Simple Inserts

- Free Catalogs

- Measuring Tools

- Home

- About us

- Sustainability

- Downloads

- Variety description add remove

- FAQ

- Contact us

-

SMOXH

add remove

SMOXH

add remove TURNING

add removeMILLING

add remove

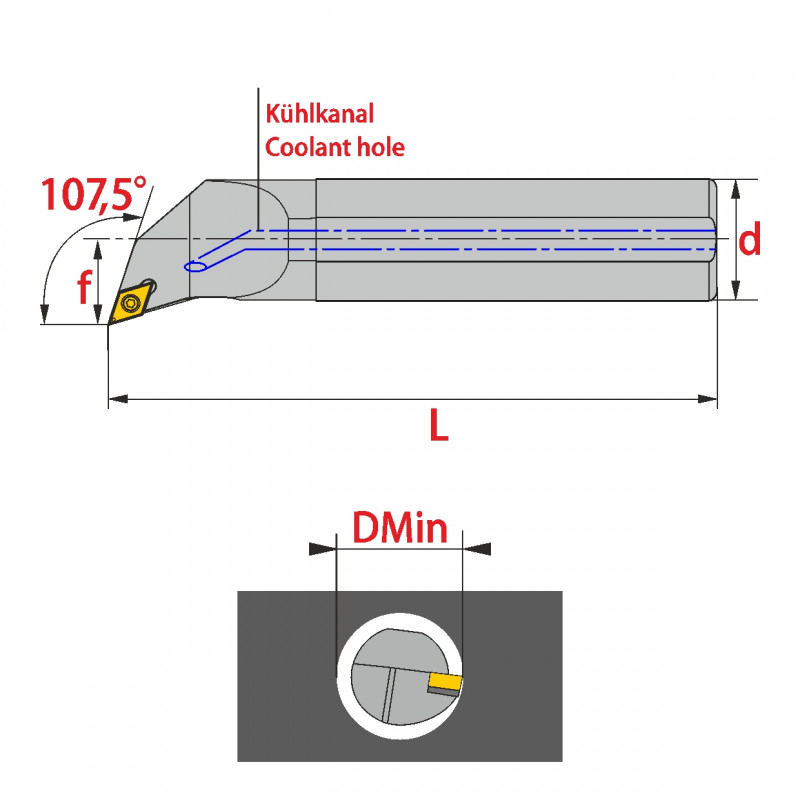

Solid Carbide Internal Tool Holder - E-SDQCR/L (107,5°) with cooling holes

| Boring Bar | E-SDQCR/L |

| Setting Angle | 107,5° |

| Insert | DC.. |

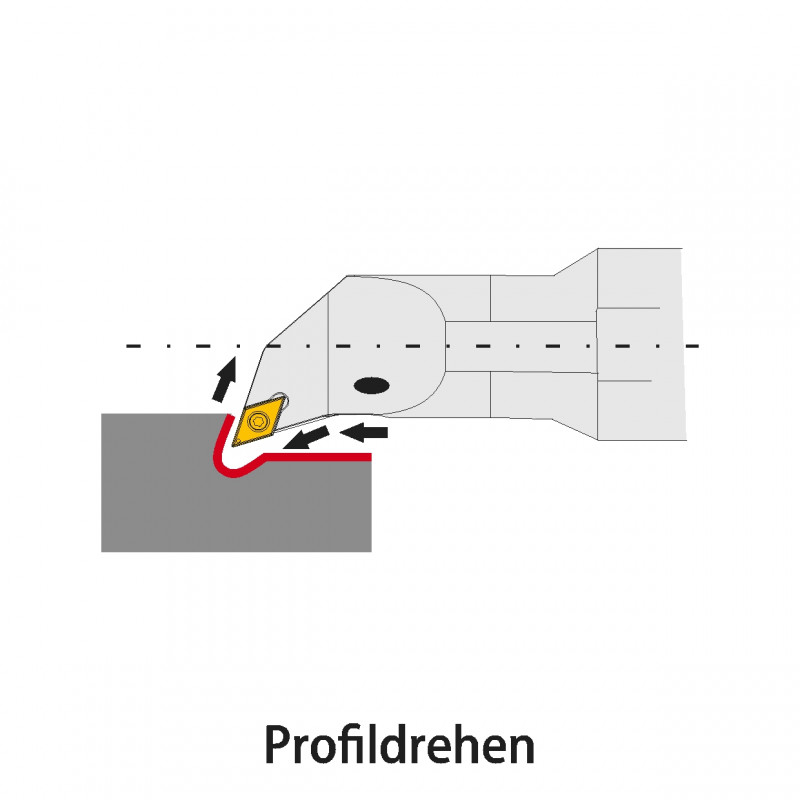

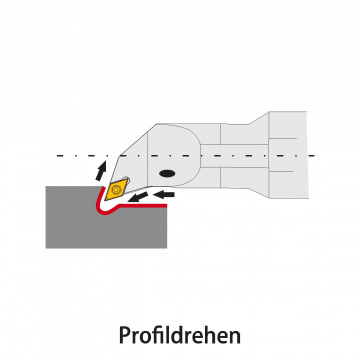

| Main application | Profile turning |

| Clamping | Screw Clamp |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

Solid carbide boring bar

Solid carbide tool carriers increase stability considerably.

The carbide boring bar allows a projection length of up to 6xD by reducing vibrations.

Precision and surface quality are also improved.

| Art. Nr. | d | L | f | D/min | Screw | |

| E10M SDQCR-07 with cooling holes | SM59979 | 10 | 150 | 08 | ≥13 | SSV M2,5x6 |

| E10M SDQCL-07 with cooling holes | SM60012 | 10 | 150 | 08 | ≥13 | SSV M2,5x6 |

| E12Q SDQCR-07 with cooling holes | SM59986 | 12 | 180 | 10 | ≥16 | SSV M2,5x6 |

| E12Q SDQCL-07 with cooling holes | SM60029 | 12 | 180 | 10 | ≥16 | SSV M2,5x6 |

| E16R SDQCR-11 with cooling holes | SM59993 | 16 | 200 | 13 | ≥21 | SSV M3,5x10 |

| E16R SDQCL-11 with cooling holes | SM60036 | 16 | 200 | 13 | ≥21 | SSV M3,5x10 |

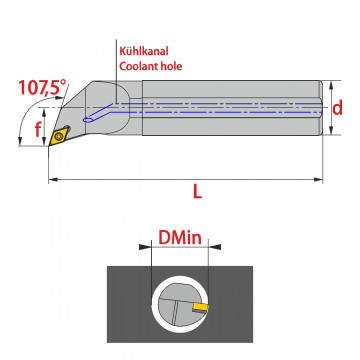

| Boring Bar | E-SDQCR/L |

| Setting Angle | 107,5° |

| Insert | DC.. |

| Main application | Profile turning |

| Clamping | Screw Clamp |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

Solid carbide boring bar

Solid carbide tool carriers increase stability considerably.

The carbide boring bar allows a projection length of up to 6xD by reducing vibrations.

Precision and surface quality are also improved.

| d | L | f | D/min | |

| E10M SDQCR/L-07 with cooling holes | 10 | 150 | 08 | ≥13 |

| E12Q SDQCR/L-07 with cooling holes | 12 | 180 | 10 | ≥16 |

| E16R SDQCR/L-11 with cooling holes | 16 | 200 | 13 | ≥21 |

Matching articles

Indexable insert - DCGT ... -ALZ RT100

| Shape | DCGT |

| Workpiece Material | NF-Materials |

| Grade | RT100: Uncoated K10-K15 carbide for ALU and plastics |

| Packaging unit | 10 Pc. |

| r | L | I.C | S | d | |

| DCGT 070201-ALZ RT100 | 0,1 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070202-ALZ RT100 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070204-ALZ RT100 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070208-ALZ RT100 | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 11T302-ALZ RT100 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCGT 11T304-ALZ RT100 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCGT 11T308-ALZ RT100 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -HM RT250

| Shape | DCMT |

| Processing | Medium |

| Worpiece Material | Steel |

| Grade | RT250: CVD-coated P25-TIN hard metal for general steel processing |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070202-HM RT250 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070204-HM RT250 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070208-HM RT250 | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T302-HM RT250 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T304-HM RT250 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-HM RT250 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -HM RT300

| Shape | DCMT |

| Processing | Medium |

| Workpiece Material | Steel and Stainless Steel |

| Grade | RT300: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070202-HM RT300 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070204-HM RT300 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070208-HM RT300 | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T302-HM RT300 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T304-HM RT300 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-HM RT300 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable CBN-Insert - DCGW ...-2N RTC20T

| Shape | DCGW |

| Scope of application | Hard turning |

| Cutting edges | 2 |

| Grade | RTC20T : TIN-coated CBN for full to lightly interrupted cuts in hardened steels |

| Packaging unit | 2 Pc |

| I.C. | S | r | d | L | |

| DCGW 070204-2N RTC20T | 6,35 | 2,38 | 0,4 | 2,8 | 2,2 |

| DCGW 070208-2N RTC20T | 6,35 | 2,38 | 0,8 | 2,8 | 2,2 |

| DCGW 11T302-2N RTC20T | 9,525 | 3,97 | 0,2 | 4,4 | 2,2 |

| DCGW 11T304-2N RTC20T | 9,525 | 3,97 | 0,4 | 4,4 | 2,2 |

| DCGW 11T308-2N RTC20T | 9,525 | 3,97 | 0,8 | 4,4 | 2,2 |

PCD-Insert - DCGW ...-1N RTD10

| Shape | DCGW |

| Processing | High Speed Alu Turning |

| Workpiece Material | Aluminum, NF-Materials |

| Grade | RTD10: Polycrystalline diamond for high-speed machining of aluminum up to 12% Si, non-ferrous metals and plastic |

| Packaging unit | 2 Pc. |

PCD = Polycrystalline diamond (PCD) is a synthetically produced, extremely hard, intergrown mass of randomly oriented diamond particles in a metal matrix.

| r | L | I.C | S | d | |

| DCGW 070202-1N RTD10 | 0,2 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGW 070204-1N RTD10 | 0,4 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGW 11T302-1N RTD10 | 0,2 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGW 11T304-1N RTD10 | 0,4 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGW 11T308-1N RTD10 | 0,8 | 2,5 | 9,525 | 3,97 | 4,4 |

PCD-Insert - DCGT ...-1N RTD10

| Shape | DCGT |

| Processing | High Speed Alu Turning |

| Workpiece Material | Aluminum, NF-Materials |

| Grade | RTD10: Polycrystalline diamond for high-speed machining of aluminum up to 12% Si, non-ferrous metals and plastic |

| Packaging unit | 2 Pc. |

PCD = Polycrystalline diamond (PCD) is a synthetically produced, extremely hard, intergrown mass of randomly oriented diamond particles in a metal matrix.

| r | L | I.C | S | d | |

| DCGT 070202-1N RTD10 | 0,2 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGT 070204-1N RTD10 | 0,4 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGT 11T302-1N RTD10 | 0,2 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGT 11T304-1N RTD10 | 0,4 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGT 11T308-1N RTD10 | 0,8 | 2,5 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -PM RT250+

| Shape | DCMT |

| Processing | Medium |

| Workpiece Material | Steel |

| Grade | RT250+: CVD-coated 2-color coated P20-P30 carbide for steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070204-PM RT250+ | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T304-PM RT250+ | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-PM RT250+ | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -PR RT250+

| Shape | DCMT |

| Processing | Roughing |

| Workpiece Material | Steel |

| Grade | RT250+: CVD-coated 2-color coated P20-P30 carbide for steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 11T304-PR RT250+ | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-PR RT250+ | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -HF RT250X

| Shape | DCMT |

| Processing | Medium and finish |

| Workpiece Material | Steel and Stainless Steel |

| Grade | RT250X = PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 11T304-HF RT250X | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-HF RT250x | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

16 other products in the same category:

Internal Tool Holder - TWLNR/L (95°) with clamping

| Boring Bar | TWLNR/L |

| Cutting Angle | 95° |

| Insert | WN.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Claw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

Particularly suitable for roughing due to stable claw clamping.

| d | h | L | f | Dmin | Insert | |

| S20R TWLNR-06 | 20 | 18 | 170 | 15 | ≥26 | WNM. 0604.. |

| S20R TWLNL-06 | 20 | 18 | 170 | 15 | ≥26 | WNM. 0604.. |

| S25S TWLNR-06 | 25 | 23 | 250 | 19,5 | ≥36 | WNM. 0604.. |

| S25S TWLNL-06 | 25 | 23 | 250 | 19,5 | ≥36 | WNM. 0604.. |

| S232T TWLNR-06 | 32 | 30 | 300 | 24 | ≥44 | WNM. 0604.. |

| S232T TWLNL-06 | 32 | 30 | 300 | 24 | ≥44 | WNM. 0604.. |

| S25S TWLNR-08 | 25 | 23 | 250 | 19,5 | ≥38 | WNM. 0804.. |

| S25S TWLNL-08 | 25 | 23 | 250 | 19,5 | ≥38 | WNM. 0804.. |

| S32T TWLNR-08 | 32 | 30 | 300 | 24 | ≥44 |

WNM. 0804.. |

| S32T TWLNL-08 | 32 | 30 | 300 | 24 | ≥44 | WNM. 0804.. |

| S40U TWLNR-08 | 40 | 37 | 350 | 30 | ≥50 | WNM. 0804.. |

| S40U TWLNL-08 | 40 | 37 | 350 | 30 | ≥50 | WNM. 0804.. |

Internal Tool Holder - SCLCR/L (95°) with...

| Boring Bar | SCLCR/L |

| Cutting Angle | 95° |

| Insert | CC.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Screw Clamping |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A08H SCLCR/L 06 with cooling holes | 8 | 7 | 100 | 07 | ≥11 | CCG./CCM. 06.. |

| A10H SCLCR/L 06 with cooling holes | 10 | 9 | 100 | 08 | ≥13 | CCG./CCM. 06.. |

| A12H SCLCR/L 06 with cooling holes | 12 | 11 | 100 | 10 | ≥16 | CCG./CCM. 06.. |

| A16M SCLCR/L 09 with cooling holes | 16 | 15 | 150 | 13 | ≥21 | CCG./CCM. 09.. |

| A20P SCLCR/L 09 with cooling holes | 20 | 19 | 170 | 15 | ≥25 | CCG./CCM. 09.. |

| A25R SCLCR/L 09 with cooling holes | 25 | 23 | 200 | 19,5 | ≥32 | CCG./CCM. 09.. |

Internal Tool Holder - TDUNR/L (93°) with clamping

| Boring Bar | TDUNR/L |

| Cutting Angle | 93° |

| Insert | DN.. |

| Main application | Profiling |

| Clamping | Claw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

Particularly suitable for roughing due to stable claw clamping.

| d | h | L | f | Dmin | Insert | |

| S25S TDUNR-11 | 25 | 23 | 250 | 19,5 | ≥33 | DNM. 1104.. |

| S25S TDUNL-11 | 25 | 23 | 250 | 19,5 | ≥33 | DNM. 1104.. |

| S32T TDUNR-11 | 32 | 30 | 300 | 24 | ≥40 |

DNM. 1104.. |

| S32T TDUNL-11 | 32 | 30 | 300 | 24 | ≥40 | DNM. 1104.. |

| S25S TDUNR-15 | 25 | 23 | 250 | 19,5 | ≥39 | DNM. 1506.. |

| S25S TDUNL-15 | 25 | 23 | 250 | 19,5 | ≥39 | DNM. 1506.. |

| S32T TDUNR-15 | 32 | 30 | 300 | 24 | ≥40 | DNM. 1506.. |

| S32T TDUNL-15 | 32 | 30 | 300 | 24 | ≥40 | DNM. 1506.. |

| S40U TDUNR-15 | 40 | 37 | 350 | 30 | ≥50 | DNM. 1506.. |

| S40U TDUNL-15 | 40 | 37 | 350 | 30 | ≥50 | DNM. 1506.. |

Internal Tool Holder - PSKNR/L (75°) with...

| Boring Bar | PSKNR/L |

| Cutting Angle | 75° |

| Insert | SN.. |

| Main application | Longitudinal turning |

| Clamping | Pin Lock |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A25R PSKNR-12 | 25 | 23 | 200 | 17 | ≥32 | SNM. 1204.. |

| A25R PSKNL-12 | 25 | 23 | 200 | 17 | ≥32 | SNM. 1204.. |

| A32S PSKNR-12 | 32 | 30 | 250 | 22 | ≥40 |

SNM. 1204.. |

| A32S PSKNL-12 | 32 | 30 | 250 | 22 | ≥40 | SNM. 1204.. |

Internal Tool Holder - SCLCR/L (95°)

| Boring Bar | SCLCR/L |

| Cutting Angle | 95° |

| Insert | CC.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | L1 | f | Dmin | |

| S0608H SCLCR/L 06 | 8 | 7 | 100 | 25 | 05 | ≥8 |

| S08H SCLCR/L 06 | 8 | 7 | 100 | - | 07 | ≥11 |

| S10K SCLCR/L 06 | 10 | 9 | 125 | - | 08 | ≥13 |

| S12K SCLCR/L 06 | 12 | 11 | 125 | - | 10 | ≥16 |

| S16x10M SCLCR/L 06 | 16 | 15 | 150 | 35 | 10 | ≥16 |

| S16x12M SCLCR/L 06 | 16 | 15 | 150 | 35 | 10 | ≥16 |

| S12K SCLCR/L 09 | 12 | 11 | 125 | - | 10 | ≥16 |

| S16P SCLCR/L 09 | 16 | 15 | 170 | - | 13 | ≥21 |

| S20R SCLCR/L 09 | 20 | 19 | 200 | - | 15 | ≥25 |

| S25S SCLCR/L 09 | 25 | 23 | 250 | - | 19,5 | ≥32 |

| S32T SCLCR/L 09 | 32 | 30 | 300 | - | 24 | ≥40 |

Internal Threading Tool Holder - SIL/TIL Left

| Boring Bar | SIL/TIL |

| Insert | Threading Inserts |

| Main application | Threading |

| Right/Left | Left |

| Clamping | Screw Clamp |

| Cooling | Without Cooling Holes |

| Packaging Unit | 1 Pc. |

Boring Bars for Threading indexable inserts Left

-11 = for 11...IL... Threading inserts

-16 = for 16...IL... Threading inserts

-22 = for 22...IL... Threading inserts

| d | d1 | h | L | f | L1 | Dmin | Insert | |

| S10K SIL-11 | 10 | 10 | 09 | 125 | 7 | - | 12 | 11...IL... |

| S12K SIL-11 | 12 | 12 | 11 | 125 | 10 | - | 16 | 11...IL... |

| S16x13M SIL-16 | 16 | 13 | 15 | 150 | 10 | 32 | 16 | 16...IL... |

| S16M SIL-16 | 16 | 16 | 15 | 150 | 11 | - | 19 | 16...IL... |

| S20P SIL-16 | 20 | 20 | 18 | 170 | 14 | - | 24 | 16...IL... |

| S25R TIL-16 | 25 | 25 | 23 | 200 | 16,5 | - | 29 | 16...IL... |

| S32S TIL-16 | 32 | 32 | 30 | 250 | 20 | - | 36 | 16...IL... |

| S25R TIL-22 | 25 | 25 | 23 | 200 | 16,5 | - | 29 | 22...IL... |

| S32S TIL-22 | 32 | 32 | 30 | 250 | 20 | - | 38 | 22...IL... |

Internal Tool Holder - SVUBR/L (93°)

| Boring Bar | SVUBR/L |

| Cutting Angle | 93° |

| Insert | VB.. |

| Main Application | Profiling |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S16P SVUBR-11 | 16 | 15 | 170 | 13 | ≥21 | VBM. 1103.. |

| S16P SVUBR-11 | 16 | 15 | 170 | 13 | ≥21 | VBM. 1103.. |

| S20R SVUBR-11 | 20 | 18 | 200 | 15 | ≥25 | VBM. 1103.. |

| S20R SVUBL-11 | 20 | 18 | 200 | 15 | ≥25 | VBM. 1103.. |

| S25S SVUBR-16 | 25 | 23 | 250 | 19,5 | ≥32 | VBM. 1604.. |

| S25S SVUBL-16 | 25 | 23 | 250 | 19,5 | ≥32 | VBM. 1604.. |

| S32T SVUBR-16 | 32 | 30 | 300 | 24 | ≥40 | VBM. 1604.. |

| S32T SVUBL-16 | 32 | 30 | 300 | 24 | ≥40 | VBM. 1604.. |

| S40U SVUBR-16 | 40 | 37 | 350 | 30 | ≥50 | VBM. 1604.. |

| S40U SVUBL-16 | 40 | 37 | 350 | 30 | ≥50 | VBM. 1604.. |

Sleeve

Packaging unit = 1 Pc.

| Ød | a | b | c | ØD | H | L | |

| SL1604 (For E04...Boring bars) | 4 | 5 | 6 | -- | 16 | 14 | 100 |

| SL1605 (For E05...Boring bars) | 5 | 5 | 8 | -- | 16 | 14 | 100 |

| SL1606 (For E06...Boring bars) | 6 | 5 | 6 | 6 | 16 | 14 | 100 |

Internal Tool Holder - PDUNR/L (93°) with...

| Boring Bar | PDUNR/L |

| Cutting Angle | 93° |

| Insert | DN.. |

| Main application | Profiling |

| Clamping | Pin Lock |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A25R PDUNR 11 | 25 | 24 | 200 | 17 | ≥32 | DNM. 11.. |

| A25R PDUNL 11 | 25 | 24 | 200 | 17 | ≥32 | DNM. 11.. |

| A32S PDUNR 15 | 32 | 30 | 250 | 22 | ≥40 | DNM. 15.. |

| A32S PDUNL 15 | 32 | 30 | 250 | 22 | ≥40 | DNM. 15.. |

Internal Tool Holder - PCLNR/L (95°) with...

| Boring Bar | PCLNR/L |

| Cutting Angle | 95° |

| Insert | CN.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Pin Lock |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A25R PCLNR/L-12 with cooling holes |

25 | 23 | 200 | 17 | ≥32 | CNM. 1204.. |

| A32S PCLNR/L-12 with cooling holes |

32 | 30 | 250 | 22 | ≥40 | CNM. 1204.. |

Internal Threading Tool Holder - SIR/TIR Right

| Boring Bar | SIR/TIR |

| Insert | Threading Inserts |

| Right/Left | Right |

| Main application | Threading |

| Clamping | Screw Clamp |

| Cooling | Without Cooling Holes |

| Packaging Unit | 1 Pc. |

Boring Bars for Threading indexable inserts Right

-11 = for 11...IR... Threading inserts

-16 = for 16...IR... Threading inserts

-22 = for 22...IR... Threading inserts

| d | d1 | h | L | f | L1 | Dmin | Insert | |

| S10K SIR-11 | 10 | 10 | 09 | 125 | 7 | - | 12 | 11...IR... |

| S12K SIR-11 | 12 | 12 | 11 | 125 | 10 | - | 16 | 11...IR... |

| S16x13M SIR-16 | 16 | 13 | 15 | 150 | 10 | 32 | 16 | 16...IR... |

| S16M SIR-16 | 16 | 16 | 15 | 150 | 11 | - | 19 | 16...IR... |

| S20P SIR-16 | 20 | 20 | 18 | 170 | 14 | - | 24 | 16...IR... |

| S25R TIR-16 | 25 | 25 | 23 | 200 | 16,5 | - | 29 | 16...IR... |

| S32S TIR-16 | 32 | 32 | 30 | 250 | 20 | - | 36 | 16...IR... |

| S25R TIR-22 | 25 | 25 | 23 | 200 | 16,5 | - | 29 | 22...IR... |

| S32S TIR-22 | 32 | 32 | 30 | 250 | 20 | - | 38 | 22...IR... |

Internal Tool Holder - SDQCR/L (107,5°)

| Boring Bar | SDQCR/L |

| Cutting Angle | 107,5° |

| Insert | DC.. |

| Main application | Profiling |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S12K SDQCR/L-07 | 12 | 11 | 125 | 10 | ≥16 | DCG./DCM. 07.. |

| S16P SDQCR/L-07 | 16 | 15 | 170 | 13 | ≥21 | DCG./DCM. 07.. |

| S16P SDQCR/L-11 |

16 | 15 | 170 | 13 | ≥21 | DCG./DCM. 11.. |

| S20R SDQCR/L-11 |

20 | 18 | 200 | 15 | ≥25 | DCG./DCM. 11.. |

| S25S SDQCR/L-11 |

25 | 23 | 250 | 19,5 | ≥32 | DCG./DCM. 11.. |

Internal Tool Holder - SDQCR/L (107,5°) with...

| Boring Bar | SDQCR/L |

| Cutting Angle | 107,5° |

| Insert | DC.. |

| Main application | Profiling |

| Clamping | Screw Clamping |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A10H SDQCR/L-07 with cooling holes | 10 | 09 | 100 | 08 | ≥13 | DCG./DCM. 07.. |

| A12H SDQCR/L-07 with cooling holes | 12 | 11 | 100 | 10 | ≥16 | DCG./DCM. 07.. |

| A16M SDQCR/L-07 with cooling holes | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 07.. |

| A16M SDQCR/L-11 with cooling holes |

16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 11.. |

| A20P SDQCR/L-11 with cooling holes |

20 | 18 | 170 | 15 | ≥25 | DCG./DCM. 11.. |

| A25R SDQCR/L-11 with cooling holes |

25 | 23 | 200 | 19,5 | ≥32 | DCG./DCM. 11.. |

| A32S SDQCR/L-11 with cooling holes | 32 | 30 | 250 | 24 | ≥40 | DCG./DCM. 11.. |

Internal Tool Holder - SDXCR/L (93°)

| Boring Bar | SDXCR/L |

| Cutting Angle | 93° |

| Insert | DC.. |

| Hauptanwendung | Back Boring |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

93° boring bar for Back Boring.

| d | h | L | f | Dmin | Insert | |

| S12K SDXCR-07 | 12 | 11 | 125 | 11 | ≥17 | DCM./DCG. 0702.. |

| S12K SDXCL-07 | 12 | 11 | 125 | 11 | ≥17 | DCM./DCG. 0702.. |

| S16P SDXCR-11 | 16 | 15 | 170 | 13 | ≥21 | DCM./DCG. 11T3.. |

| S16P SDXCL-11 | 16 | 15 | 170 | 13 | ≥21 | DCM./DCG. 11T3.. |

| S20R SDXCR-11 | 20 | 18 | 200 | 15 | ≥25 | DCM./DCG. 11T3.. |

| S20R SDXCL-11 | 20 | 18 | 200 | 15 | ≥25 | DCM./DCG. 11T3.. |

Internal Tool Holder - TCLNR/L (95°) with clamping

| Boring Bar | TCLNR/L |

| Cutting Angle | 95° |

| Insert | CN.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Claw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

Particularly suitable for roughing due to stable claw clamping.

| d | h | L | f | Dmin | Insert | |

| S20R TCLNR-12 | 20 | 18 | 170 | 15 | ≥26 | CN.. 1204.. |

| S20R TCLNL-12 | 20 | 18 | 170 | 15 | ≥26 | CN.. 1204.. |

| S25S TCLNR-12 | 25 | 23 | 250 | 19,5 | ≥38 | CN.. 1204.. |

| S25S TCLNL-12 | 25 | 23 | 250 | 19,5 | ≥38 | CN.. 1204.. |

| S32T TCLNR-12 | 32 | 30 | 300 | 24 | ≥40 |

CN.. 1204.. |

| S32T TCLNL-12 | 32 | 30 | 300 | 24 | ≥40 | CN.. 1204.. |

| S40U TCLNR-12 | 40 | 37 | 350 | 30 | ≥50 | CN.. 1204.. |

| S40U TCLNL-12 | 40 | 37 | 350 | 30 | ≥50 | CN.. 1204.. |

| S40U TCLNR-16 | 40 | 37 | 350 | 30 | ≥44 | CN.. 1606.. |

| S40U TCLNL-16 | 40 | 37 | 350 | 30 | ≥44 | CN.. 1606.. |

| S50V TCLNR-12 | 50 | 47 | 400 | 38 | ≥63 | CN.. 1204.. |

| S50V TCLNL-12 | 50 | 47 | 400 | 38 | ≥63 | CN.. 1204.. |

Internal Tool Holder - PCLNR/L (95°)

| Boring Bar | SPCLNR/L |

| Cutting Angle | 95° |

| Insert | CN.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Pin Lock |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S25S PCLNR/L 12 | 25 | 23 | 250 | 17 | ≥32 | CN.. 12.. |

| S32T PCLNR/L 12 | 32 | 30 | 300 | 22 | ≥40 | CN.. 12.. |

| S40U PCLNR/L 12 | 40 | 37 | 350 | 27 | ≥50 | CN.. 12.. |

| S40U PCLNR/L 16 | 40 | 37 | 350 | 27 | ≥50 | CN.. 16.. |